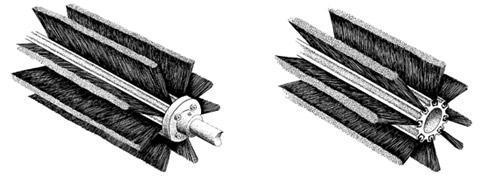

Save time and money by replacing just the worn brushes! SEALEZE® rotary strip brushes are easy to assemble and disassemble, making changing brushes quick and easy.

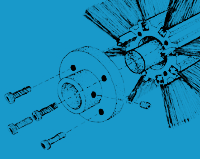

Custom rotary strip brushes are available in two sizes: D Series and G Series. Extrusions are made from aluminum alloy. Machined aluminum alloy mounting hubs are available. Hubs for D Series rotary brushes enable mounting on shafts with 0.750 inch diameter; hubs for G Series rotary brushes enable mounting on shafts with 1.000 inch diameter. Brush channel materials include galvanized steel and T-304, T-304L, T-316 and T-316L stainless steels. A wide variety of filament materials is available (including crimped and level) with a wide selection of filament diameters. Custom mandrels and hubs can be designed and manufactured, upon request.

SEALEZE® rotary strip brushes are designed for low-RPM applications, typically less than 100 RPM.

If your application requires rotary strip brushes with special requirements, contact a SEALEZE® Sales Representative for more information.

To email us your application information, click here. Or, call 1-800-787-7325.

| Rotary Strip Brush Assemblies | |||

|---|---|---|---|

| Extrusion Dimensions | Minimum Assembly with Brush | ||

| OD | ID | OD | |

| Series D | 2.220 | 1.125 | 3.18 |

| Series G | 2.743 | 1.375 | 4.25 |

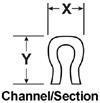

| Channel Section Size | |||

| Section Size | (X) Width (inches) | (Y) Height (inches) |  |

| D | 0.240 | 0.256 | |

| G | 0.350 | 0.370 | |

Download a worksheet for Series D Rotary Brushes, worksheet for Series G Rotary Brushes or, go to the online Rotary Strip Brush worksheet.